Table of Contents

ToggleImagine transforming your wildest ideas into reality with just a few clicks. 3D printing isn’t just for tech wizards anymore; it’s for anyone with a spark of creativity and a dash of curiosity. Whether you want to create a quirky coffee mug or a life-sized dinosaur (because who wouldn’t?), the world of 3D printing opens doors to endless possibilities.

Understanding 3D Printing

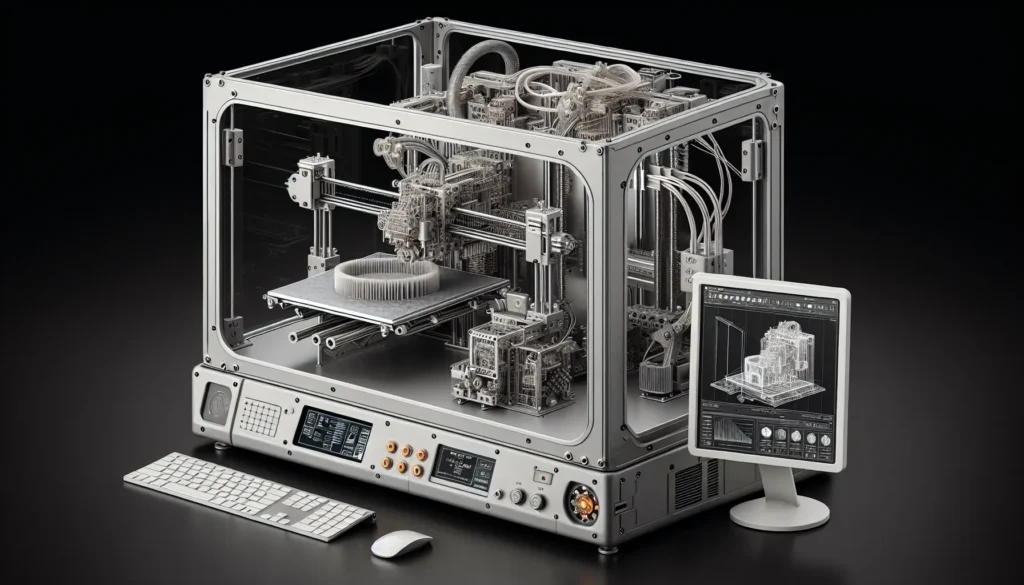

3D printing refers to the process of creating three-dimensional objects from digital files. This technology uses additive manufacturing, where materials are added layer by layer to build the final product. With various techniques available, such as FDM (Fused Deposition Modeling) and SLA (Stereolithography), each method suits different material types and object complexities.

Materials used in 3D printing vary widely. Common choices include plastic, resin, metal, and even biological materials for medical applications. Each material provides distinct attributes, affecting strength, flexibility, and durability. For example, PLA (Polylactic Acid) is a popular bioplastic, prized for its ease of use and eco-friendliness, while ABS (Acrylonitrile Butadiene Styrene) offers increased toughness for functional parts.

The process begins with a 3D model, typically created using CAD (Computer-Aided Design) software. Designers can also download existing models from online repositories. Once a model is in place, slicing software converts it into instructions for the printer, determining layer thickness and fill density.

Successful 3D printing requires careful setup and maintenance. Calibration ensures print accuracy, while regular cleaning maintains printer performance. Users may also need to adjust settings to optimize print quality based on the chosen material and model complexity.

Applications of 3D printing span various fields. Industries utilize this technology for prototyping, manufacturing, and even custom parts creation. Education and hobbyists explore 3D printing to enhance creativity, producing everything from art pieces to functional tools. The potential of 3D printing continues to expand, making it an invaluable resource for innovation.

Choosing the Right 3D Printer

Selecting the right 3D printer significantly influences the overall experience and outcomes of printing projects. Several factors, including printer type and key features, determine suitability for specific needs.

Types of 3D Printers

Fused Deposition Modeling (FDM) printers remain popular for beginners due to their affordability and ease of use. Stereolithography (SLA) printers offer high precision for detailed designs, often preferred for jewelry or model making. Selective Laser Sintering (SLS) printers utilize a laser to fuse materials, ideal for functional parts and complex designs. Delta printers, known for faster print speeds, excel in creating taller models. Each type caters to different materials and project requirements.

Key Features to Consider

Build volume represents the maximum size of objects printed and varies between models. Print resolution determines layer thickness, affecting surface finish and detail in the final product. Material compatibility matters, as certain printers work with specific filament types or resins. Look for a user-friendly interface that simplifies the printing process. Connectivity options, like USB or Wi-Fi, enhance convenience by allowing direct input from computers or networks. Maintenance requirements significantly affect long-term use, ensuring the chosen printer remains reliable and functional.

Preparing Your Design

Preparing a design for 3D printing involves several crucial steps. Selecting the right software and file formats is essential for successful printing.

Software Options

Various software options cater to different skill levels and project types. For beginners, tools like Tinkercad or SketchUp provide user-friendly interfaces. Advanced users might prefer software such as Blender or Fusion 360, which offer greater control and complexity. Many of these applications not only allow for creative modeling but also include features for optimizing designs for 3D printing. Choosing software that meets specific design needs enhances the overall printing experience.

File Formats

File formats play a pivotal role in compatibility with 3D printers. The most common format is STL, which effectively represents 3D models in a way that printers can understand. Other formats like OBJ and AMF may offer additional features such as colors and textures but might not be supported by all printers. Before proceeding with the print, it’s crucial to ensure that the chosen format aligns with the printer’s requirements to avoid issues during the printing process. Adopting the right file format streamlines the transition from design to actual printed object.

The 3D Printing Process

3D printing involves several steps that ensure successful production. Each phase requires attention to detail and precision.

Setting Up the Printer

Setting up a 3D printer begins with placing it on a stable, flat surface. Next, users must connect the printer to a power source and, if necessary, to a computer via USB or Wi-Fi. Calibrating the print bed is critical; leveling it ensures the first layer adheres properly to prevent issues during printing. Once calibrated, users can adjust the nozzle height to the appropriate distance from the bed for optimal material flow. Finally, checking the printer’s firmware for updates helps maintain functionality and performance.

Loading the Filament

Loading filament involves carefully selecting the right material for the intended print. Users need to ensure the filament type matches the printer’s specifications, such as FDM compatibility. Insert the filament spool into its holder to allow free movement. Feeding the filament into the extruder’s entry point comes next; this might require warming up the nozzle first. As the filament reaches the hot end, it melts and flows through the nozzle onto the print bed. A successful load results in a smooth extrusion that indicates the printer is prepared for the upcoming project.

Post-Printing Finishing Techniques

Post-printing finishing techniques enhance the overall appearance and functionality of 3D printed objects. These final steps transform prints into polished pieces ready for use.

Cleaning and Support Removal

Cleaning a 3D printed item ensures a smooth final product. Use isopropyl alcohol for models printed with resin, as this effectively removes any leftover material. For those with support structures, pliers or cutters help detach supports without damaging the object. Ensure to check for any additional remnants in hard-to-reach areas, as residue can affect aesthetics and functionality. Rinsing the object under water may also assist in eliminating dust or debris, leaving a clean surface for further treatments.

Painting and Coating

Painting adds color and depth to 3D prints, making them visually appealing. Acrylic paints work well, as they bond easily to plastic surfaces. Start by applying a primer coat to enhance adhesion and create an even base. Once dried, use fine brushes for detailed work and spray paint for larger areas. Clear coatings can provide protection against scratches and UV damage, enhancing longevity. Consider applying multiple layers for a more vibrant finish, ensuring each layer dries completely before proceeding.

3D printing opens up a world of creativity and innovation for everyone. By understanding the process and selecting the right tools and materials, anyone can turn their ideas into tangible objects. With diverse applications across various industries and hobbies, the potential for 3D printing is virtually limitless.

As users gain experience in design and printing techniques, they’ll find new ways to express their creativity. The journey doesn’t end with the print itself; post-processing methods can elevate the final product, ensuring it meets their vision. Embracing 3D printing can lead to exciting projects and endless possibilities, making it a valuable skill in today’s tech-driven world.